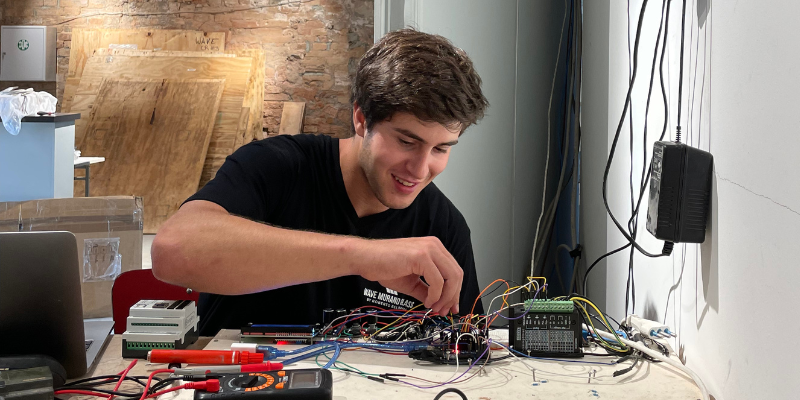

Meet Andrew. Andrew was a recent intern at Wave. He is from Beaverton Oregon, just outside of Portland, but is studying mechanical engineering at the University of Southern California. We took the time to speak to him about this internship project, how he came to be at Wave and what’s next.

How did you find this opportunity with Wave?

My friend completed an internship with Wave in 2022, which is how I found out about it. I then reached out to Roberto to see if there were additional engineering projects I could help with. The project put forward by Roberto was separate from the project completed by my friend in 2022, and required entirely new and specialised devices.

What interested you about completing an internship with Wave?

I was really interested in not only traveling abroad but also to have full control of my own project. Most engineering internships, especially as an underclassman, are more focused on supporting the work of others without doing too much hands-on work. Roberto really let me take full control of this project. In my initial interview with Roberto, I was honest and said I wasn’t sure how to even start such a project, much less develop a data acquisition and automation system from scratch. But he insisted that I would learn on the job and that has been really exciting and rewarding.

Can you tell us a little about your project with Wave?

My main project at Wave is automating the flue system for the main furnace.

So, what does that mean?

Within the furnace, you have one inlet for hot air to enter the furnace, and two outlets for the air to leave. In other words the air comes in through the heating system, and leaves either out the door where glass is gathered, or out the chimney flue in the recuperator (the part of the furnace that reheats air). The goal of this internship was to optimise the pressure of the air in the main furnace chamber when steady state air flow has been achieved. As more positive pressures are experienced, air density calculations for compressible flow indicate a larger amount of air will flow out of the main door. So if you’re a glass blower gathering, this means that the 1100°C air from the furnace will be directed towards you posing a safety risk. But as more negative pressures are experienced, the colder air from outside the door will come into the furnace chamber and will greatly decrease gas efficiency adding unnecessary costs.

So I am utilising this system to read pressure and temperature data, and control a stepper motor that opens and closes the exit at the chimney flue. Two Arduinos (an open-source electronics platform for making interactive projects) control the data acquisition and logic base, which determines how the motor should move. This ensures pressure can be regulated to a set point, as well as utilises the relationship between pressure and temperature to aid in minor temperature regulations increasing gas efficiency.

Can you explain these programs or systems a little more and how you have built out this?

Currently, I am finalizing the scripting for the Arduinos. Arduino is an open-source electronics platform intended for anyone making interactive projects (Arduino, 2023). This project requires interaction between the motor which physically opens and closes the chimney flue, two Arduinos, the main PLC (Programmable Logic Controller) for the furnace, temperature and pressure sensors, and many other electrical components using advanced transmission and communication techniques to ensure temperature and pressure can be measured and regulated without issues.

Using Arduino has been great as it is fully customisable. I have written a very robust code base which in laymen terms utilises ‘if else statements’ or what’s called conditional programming to determine what action the motor will take to regulate the furnace.

Conditional statements are used to perform different actions based on different conditions. This short Javascript tutorial provides a great overview using the example of conditional programming whether a platform would say ‘good morning’,’ good day’ or ‘good evening’ to the user. EG: If time is less than 10:00, create a “Good morning” greeting, if not, but time is less than 20:00, create a “Good day” greeting, otherwise a “Good evening”. This same programming style is what Andrew has used to open or close the flue based on the current pressure within the furnace chamber.

I also had to take a lot of data by hand to calibrate the pressure and temperature sensors so I could get accurate readings. This data then gives a curve of pressure or temperature in terms of the electrical signal given by the device. This data is then imputed into the Arduino code base and determines how much the chimney flue should open or close. This is important as time is needed for the furnace system to reach steady state equilibrium, which is basically when the temperature and pressure stop changing.

Finally, what were your goals from this experience with Wave?

When I talked to Roberto about taking on this project, he mentioned one of my main tasks would be this electrical engineering project. In my college I work mostly on chemical and manufacturing engineering within the rocket club, and I am studying mechanical engineering. So prior to starting, I really had no experience with any component in this controller system. I was able to take this opportunity to quickly learn new skills and gain hands-on engineering experience. Managing and learning about this entire project, as well as a couple others, in just a few weeks has been an incredible learning experience and will undoubtedly help me in any future career.

If you are interested in an internship opportunity with Wave, please reach out

Please contact us via the form on our contact page.